Elevate Your Ice Cream Production with AxFlow’s Tailored Solutions

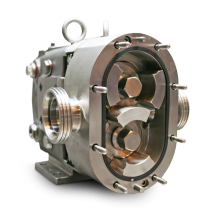

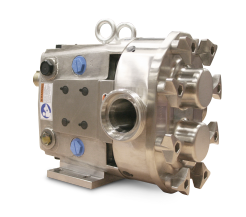

In the delectable world of ice cream creation, precision is paramount. AxFlow understands the intricacies involved, especially when it comes to processes like coating ice lollies with smooth, velvety chocolate. Our specialized rotary piston pumps are the heartbeat of efficient ice cream production, ensuring a seamless flow of ingredients. Here's how AxFlow can transform your ice cream manufacturing process:

Our Specialized Solution:

- Specifically designed for delicately circulating chocolate during ice cream production, ensuring a flawless coating process.

- Gentle on the product, these pumps maintain the chocolate's integrity, delivering an optimal result for further processing.

- Built for longevity, these pumps are ideal for permanent installation in production plants, minimizing downtime and repair costs.

Why Choose AxFlow

- Expertise: With extensive industry knowledge, AxFlow understands the nuances of ice cream production, offering tailored solutions for optimal results.

- Reliability: AxFlow’s rotary piston pumps are renowned for their reliability, ensuring consistent performance even in the most demanding production environments.

- Cost-Efficiency: By minimizing downtime and repair costs, our pumps contribute to significant savings, enhancing the overall efficiency of your production process.

- Product Integrity: Our pumps are engineered to handle delicate products like chocolate, preserving their quality and texture throughout the production cycle.

Benefits of AxFlow's Solutions

- Optimal Coating: Achieve perfect chocolate coatings on ice lollies, ensuring an appealing appearance and delightful taste.

- Extended Pump Lifespan: Our rotary piston pumps boast exceptional durability, offering a prolonged service life for enhanced productivity.

- Reduced Downtime: Minimize production interruptions with our reliable pumps, ensuring a smooth and continuous manufacturing process.

- Cost Savings: Lower repair and maintenance costs, making your ice cream production more cost-effective and sustainable in the long run.

Elevate Your Ice Cream Production with AxFlow

Partner with AxFlow to revolutionize your ice cream production. Our specialized rotary piston pumps are engineered to meet the unique challenges of ice cream coating processes, ensuring top-quality products that delight consumers. Experience seamless operations, optimal product integrity, and cost-efficiency with AxFlow’s tailored solutions. For personalized consultations and expert guidance, contact AxFlow today.